02/10/2017

3D printing a new backpack strap buckle

My backpack strap buckle just broke, and I've been walking around with the upper and lower straps tied to one another, meaning my backpack straps aren't adjustable anymore. Here's a picture of the existing buckle.

While there are replacements online, the top strap loop is sewn into the buckle. Though I could cut it and thread it into a new buckle, I wasn't confident I would be able to sew the nylon strap and have it be as strong as the factory seam. I thought I could print a new buckle that would allow for the loop to be threaded in and then secured with a bolt for strength. Here's what I came up with, one of my first designs in Fusion360, which I'm enjoying, but still getting used to.

This is where I think 3D printing is beautiful. I didn't have a normal bolt and nut of the correct size, all I had was a toggle bolt in my odds and ends box. The toggle bolt has a little threaded insert in the middle of the "wings" of the toggle, which I removed using some pliers. I dimensioned the insert out and made an indention in one side of the buckle design. I also designed the width of the buckle around the length of the bolt, so that I wouldn't have too much bolt sticking out of the nut.

The design has a lot of overhangs, mainly the big cylinder which the bolt passes through, the teeth of the cinch part, and the curved edge of the top surface (which is unbridgeable). I could have used the built-in supports in Slic3r or Cura, but I've been hearing a lot about these tree supports in Autodesk's Meshmixer so I decided to give them a try. Here's what meshmixer came up with.

Here's how the part came out on the printer, and the supports separated with ease. I was very surprised the tiny stems of the trees didn't collapse during the print.

The toggle bolt insert popped right in to the recess I modeled (which was very satisfying). I was able to squeeze the nylon loop between the opening between the bolt sheath in the buckle, then expand it over the sheaths, before sliding the bolt through. The whole thing works a charm.

02/5/2017

prusa i3 mk2 assembly + first prints

After a few months of waiting, my Prusa i3 mk2 finally turned up in the mail!

I deliberated a lot over which printer to order, and while there's really not a best choice, the Prusa i3 might be close. It's a hard balance between price, convenince, support and reliability. I wanted something that I didn't have to tinker with too much to get to print, since my main reason for wanting a 3D printer was not to have a 3D printing hobby, but to make things. -- I wouldn't want a drill that I had to re-assembly every time I wanted to drill a hole.

The kit is of incredibly good quality. Each step in the manaul has an individually labeled bag of printed parts and bag of hardware. The bags have an inventory on them to make sure you have everything needed. The inventory is even in 1:1 scale, to help identify different length bolts and different sized nuts. The instructions themselves were excellent. I only had some trouble in one or two places where I tried to get ahead of the manual.

There was only about ten hours between opening the box and taking my first print off the bed, including coffee and dinner breaks. You can see a timelapse of the build and first print in the video below, the latter half of which involves me watching Seinfeld. One of my best friends (and 3D printing veteran) Austin was with me for the first half of the build, which made it super fun.

(I didn't have a tripod or anything to mount my iPhone on to take the timelapse, but I did have some spare 1x6 and 1x4, a toggle bolt (no wood screws at the time) and some zipties. So I created this makeshift bipod which worked a charm.)

The only issues I had during the construction was forgetting to embed a nut in the extruder assembly, which made me take the assembly almost completely apart to get the nut in the right place. I also had some issues routing all of the wires that come off of the extruder through their channels, but after some fanagling it was just fine. I also had a brief scare when turning the printer on for the first time: I couldn't get past the language selection screen. Turns out I kept hitting the "X" button on the front panel, which does a hardware reset on the driver board. It took a quick Google to realize that the rotary knob also has a button built in. At least I wasn't alone.

test prints

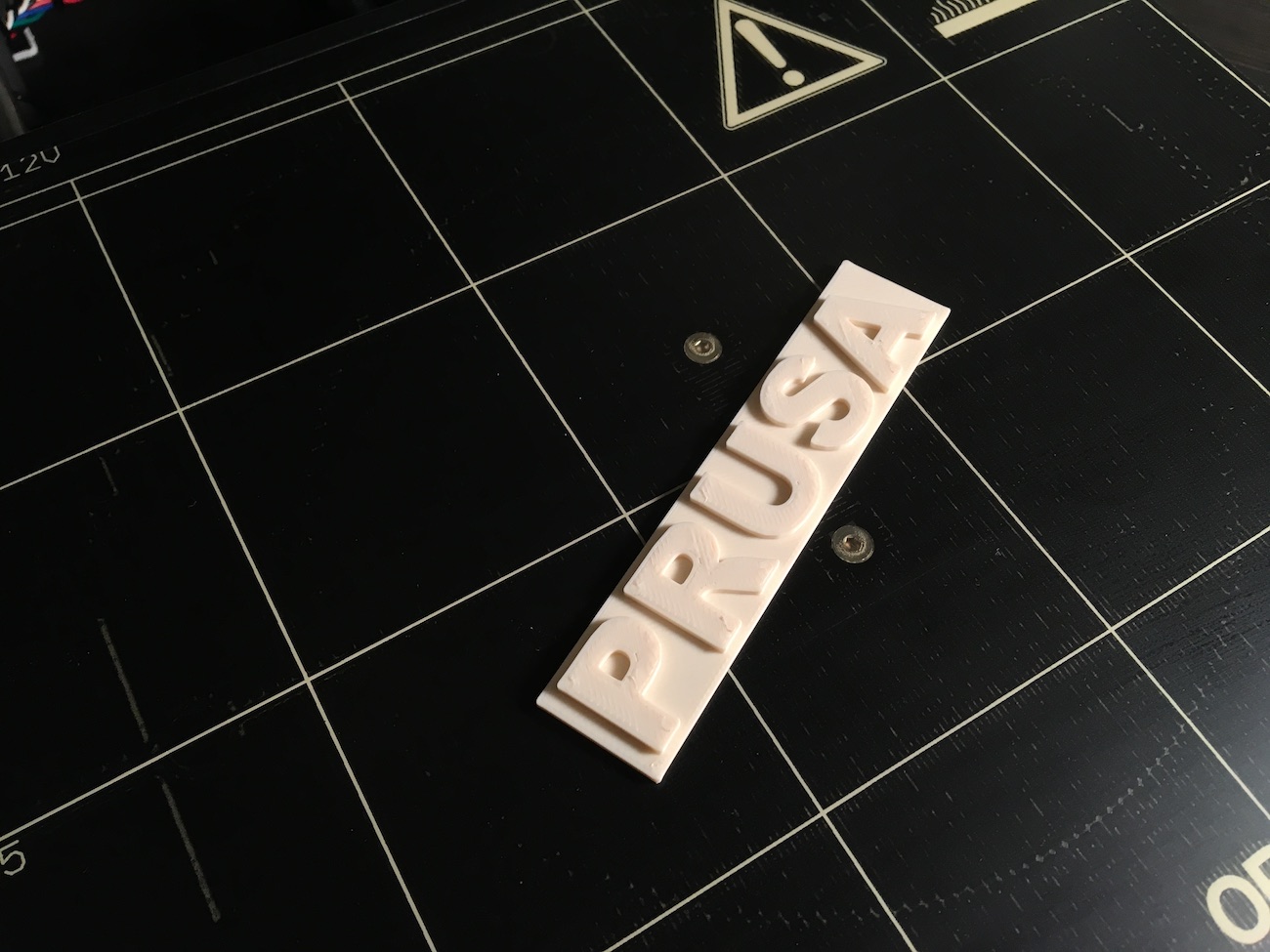

So the first print I did was the included Prusa logo badge, which helped me get through the process of adjusting the live-z value correctly. The printer has an inductive probe to measure any XY skew in the printer frame as well as any warping of the bed, but it needs a reference height to tell it exactly where it is above the bed. The process of setting this for the first time was a bit nerve-racking as the hotend looks as it's going to plunge directly into the bed while doing a Z traverse. Here's a video from Prusa themselves explaining the concept behind their calibration method.

I also printed the whistle that was included, which was my first time watching the printer pull off a bridge, very exciting. The last thing I printed before trying one of my own models was this vase, which blew me away. It took about seven or eight hours of print time, which it handled no problem. There was very little banding on the print, which I was really excited about.

designing + slicing + printing

I wanted to print something of my own, but didn't have anything ready. I looked around and thought my torx drivers could deserve not being on my desk anymore, so I modeled up this little holder in Solidworks. I'd already used Slic3r a bit, so I loaded in the Prusa provided material and slicing presets and I was off. Very, very easy. Seeing something on your computer screen and then holding it in your hands just a few hours later might never get old.

I also played a bit with modifying meshes in Fusion360 (something I've used very little of before) to remove the "JP" initials from the whistle model that shipped with the printer (sorry Josef). I printed two more whistles at 150% and 50% size, which was very fun. The small one took less that ten minutes to print.

I don't have much more to report, other than I'm extremely happy with my purchase and I can't wait to print more stuff.

01/12/2017

replacing an office chair gas cannister

The office chair I use in my apartment has had a broken gas cylinder for a while now. I couldn't adjust the height of the chair, as soon as I sat down, it was at its lowest adjustment. It also won't stay down. Every time I stand up it springs back to its maximum extension. This got annoying pretty quickly, so I fixed this problem temporarily by tying some paracord around the frame of one of the arms and the base of the chair, this kept the chair locked in its lowest position.

One of the things I got over the holidays was a new gas cylinder. I was eager to replace it, except most of the replacement procedures call out a pipe wench which I didn't have. The cylinder press fits into both the base of the chair and the seat bottom. On some models the piston can be hammered out from both the top and the bottom, but on my chair the top of the piston wasn't exposed, even if the chair bottom was removed from the metal mount. I wasn't about to buy a $20 pipe wrench to repair a chair worth less than that, so I had to improvise. I tried my channellocks first to no avail.

I remembered I had bought some half inch diameter tool steel earlier in the year (I was thinking about making my own engraving tools) that was going unused. My drill bit set conveniently goes up to a half inch drill, so naturally, I started drilling. I drilled a pilot hole first, and then did a size between my pilot and the 1/2 inch bit, before finally drilling the hole to its final size.

After the hole was drilled, I was able to insert the steel rod into the hole and rotate. Worked a charm! Now I have a perfectly functional chair again.

If you're going to go this route, I would suggest not doing it in your kitchen. The metal shavings are difficult to hunt down and pick out of the kitchen mats. -- Also, anticipate some gas release from the inside of the cylinder.